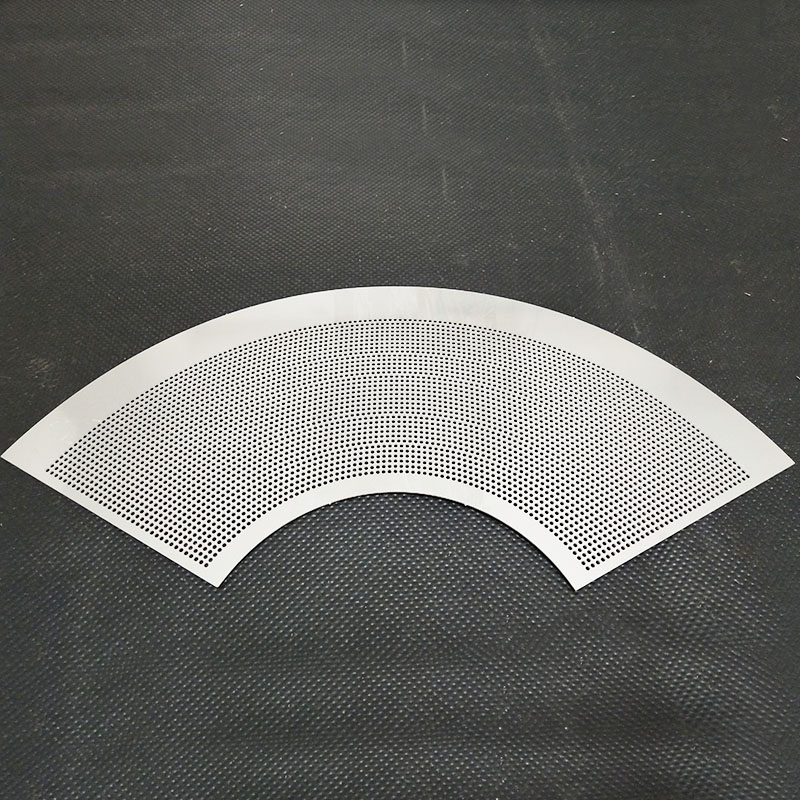

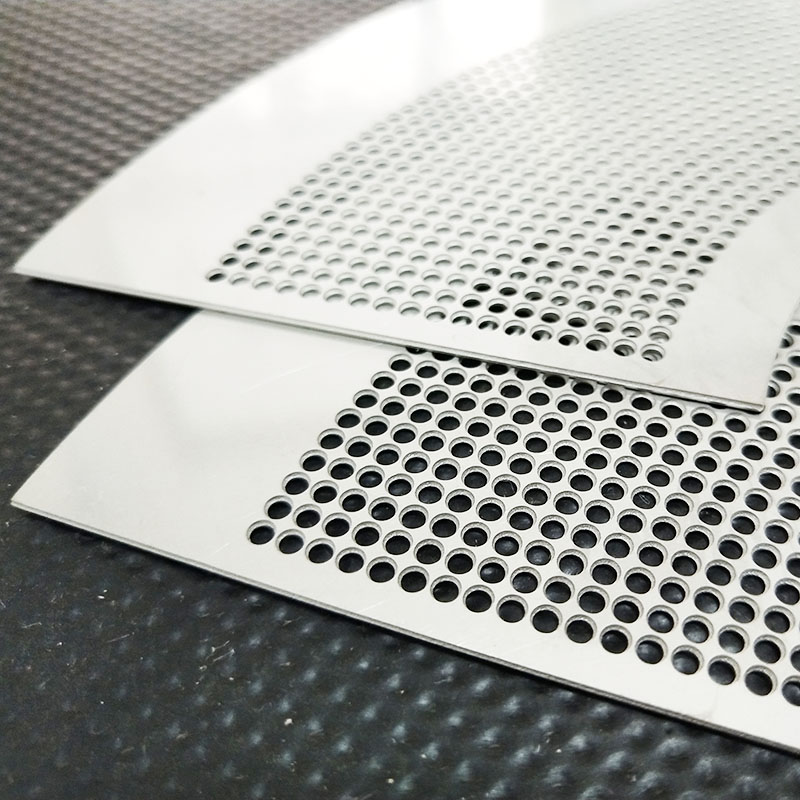

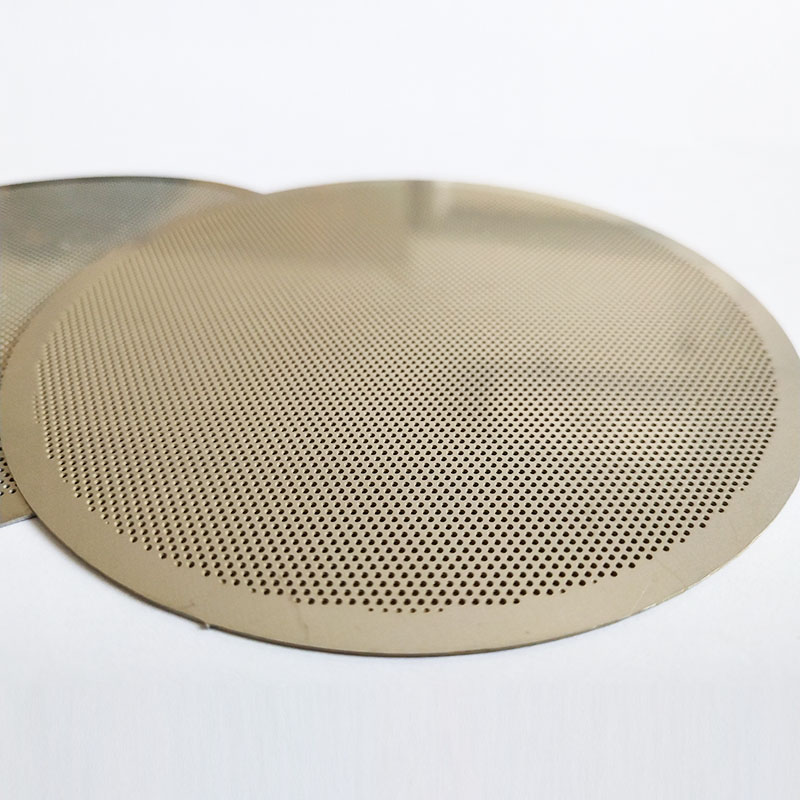

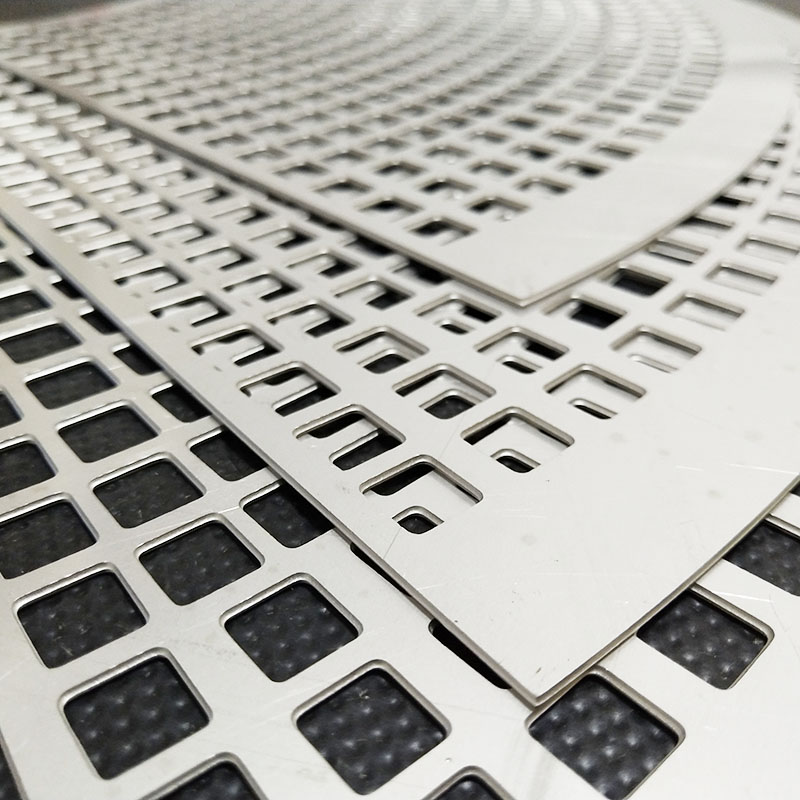

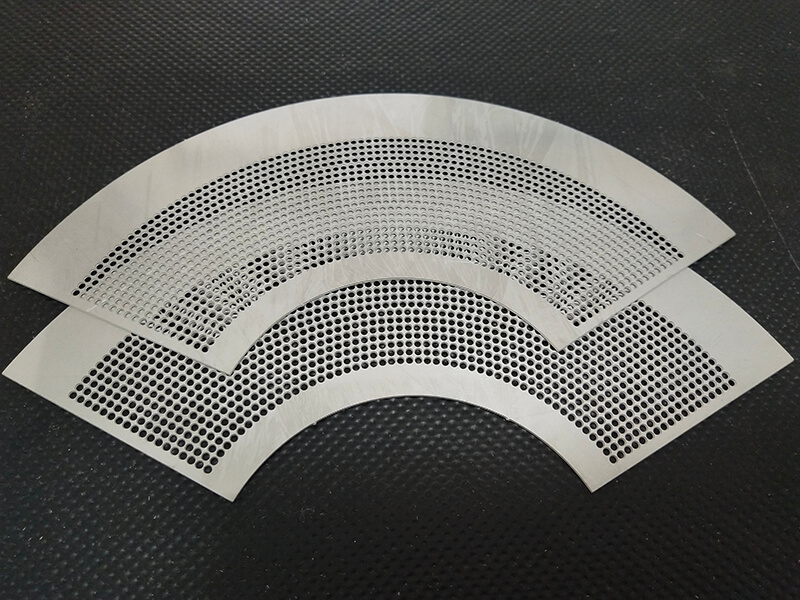

Etched Metal Filter Screen

Application:

- Circuit boards

- Water filtration

- Oil control valves

- Speaker grill

- Air intake grill

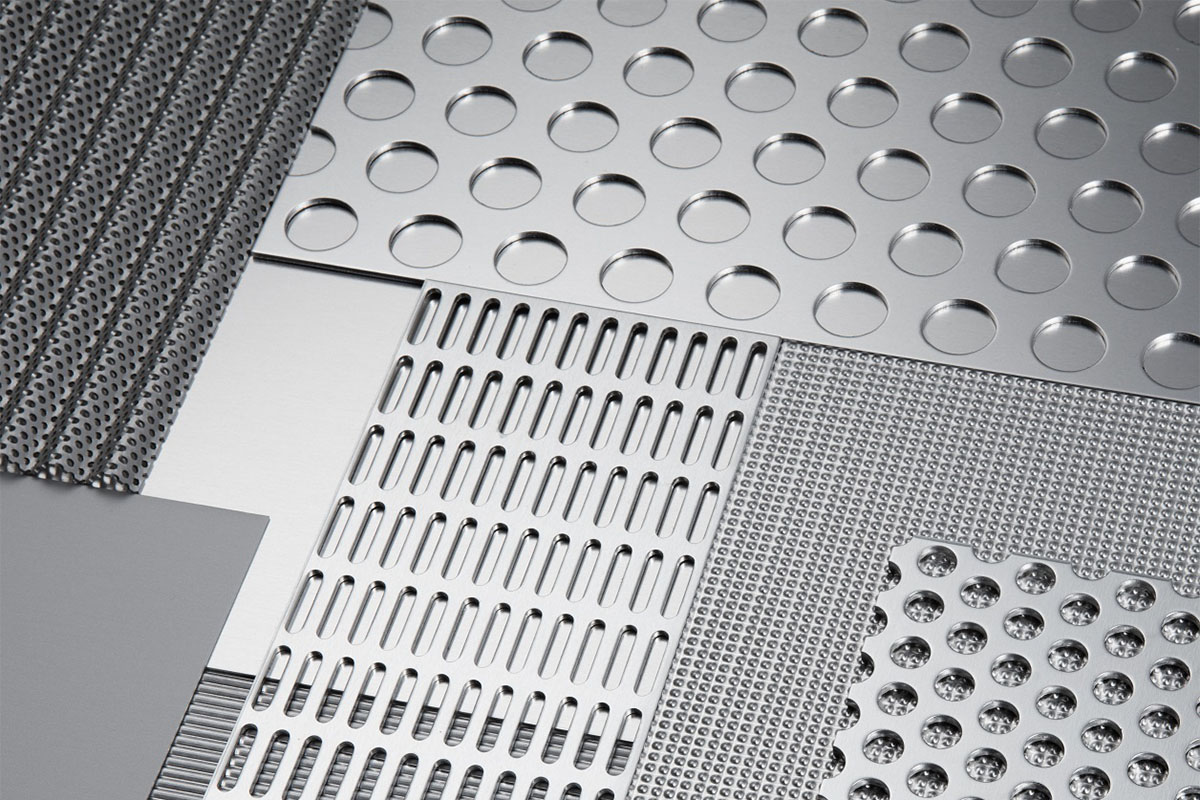

Material:

- SS 304

- SS316L

Benefits of Metal Etching:

- Short lead time making it cost-efficient

- No heat or force used during production resulting in stress/tension free product

- Use of digital tool for quick prototype

- Free from any burrs

Process of Metal Etching:

- Photo Tool/Designing – the creation of design using CAD software

- Preparation of Materials – Remove any dirt or grease on the material to ensure that the coating would adhere to the material. Material is cut to the specified size.Photo Resist Coating –application of UV light-sensitive coating to the material

- Photo Resist Exposure – Curing of the material through exposure to high-intensity light. Timing and light intensity are essential to ensure that the photocured on the material.

- Photo Developing – A liquid chemical bath is sprayed to the material to remove excess parts of the image, allowing only the image to stay and harden it.

- Etching– The metal sheets are given an aqueous ferric chloride bath where the unwanted part of the design is etched away. The bath is maintained to a precise composition to ensure a constant etching rate while minimizing its impact in the environment.

- Quality Control– Photoresist is removed from the metal sheet, and then it will undergo strict quality control to ensure that the material pass quality inspection.

Get Quote